The PHE 500 is an accessory device designed for use in conjunction with Central Hydronic Glycol Heaters. It transfers heat from the primary heated glycol circuit to another liquid that is being pumped through the secondary circuit. By using the PHE 500, three important factors can be addressed that occur in certain heating applications, these are:

- Water or other compatible fluids can be pumped through the secondary circuit of the PHE 500 and can be heated without fear of contamination from the primary glycol circuit, which allows for unlimited possible processes (ex. domestic water heating for temporary or long-term needs such as field kitchens, showers and washrooms – quick preheat of outdoor swimming pools allows for earlier opening dates – multi-purpose water tanks in construction, oil, gas and mining industries. Additional inline filters may be required if the water is brackish or full of materials that could plug up the exchange unit)

- The PHE 500 allows the user to go up many floors for applications such as temporary heat for high rise buildings, with no danger of the fluid running back and overflowing at the vented reservoir on the Central Hydronic Heater. The PHE 500 provides separation of the 2 circuits of hot glycol and there are no open vents on the PHE 500 to allow for run-back in the event the pump should quit. Expansion allowance in the secondary circuit is achieved by attaching a remote reservoir to the primary return line at the highest point in the fluid loop. This can be used for filling and adding fluid to the secondary circuit

- Separation of the fluid into two circuits eliminates the addition of pressure being exerted on the chamber of the Central Hydronic Heater, due to water column pressure of elevated fan coils when heating multi-story buildings. The PHE 500 provides the user with a safe and easy way to eliminate the necessity of conformance to pressure vessel codes

The PowerCoil 500 can be used to heat any type of liquid in most any size or shape of the container

- Water varying from potable to sea water, to the most brackish pond water – all of these and more can be heated with this coil

- After being properly cleaned and sanitized, the stainless steel coil can be used to heat any large volume of food-grade liquid that may be contained in a large tank or vat

- Any liquefied corrosive chemicals contained in a large tank can be heated to keep from freezing or to thaw back to liquid or heat up to the useable application temperature

- Petroleum products can be safely heated in large tanks for applications such as; keeping diesel fuel from gelling so it will flow to burners and motors, warming crude oil or bunker oil enough to allow it to be pumped

- Environmental cleanup operations often result in various liquids and mixture stored in tanks that become very thick at cooler temperatures. This open-loop stainless coil is the easiest and most effective way to heat these mixtures to a point where they become liquefied enough to pump or drain from the tank; this can also make it possible to skim oil off the surface of the water

Advantages:

- Built completely from stainless steel, including framework, quick couplers and optional pipe extensions. This will allow it to be immersed in tanks containing a variety of chemicals that would be corrosive to other materials

- After being properly cleaned and sanitized, the stainless steel coil can be used to heat any type of potable or food-grade liquid

- The open un-enclosed construction of the Power Coil 500 provides a couple of huge advantages that would not exist if the coil was enclosed

- No electrical or combustion related components, so no power of fuel supply is required in or near the tank. This provides a safe means of heating fluids that may off-gas explosive vapours when heated. The CHH can be safely placed up to 200 feet away, if necessary, by adding additional glycol hoses. This is the safest way possible to get heat into an explosive environment

- If corrosive chemical is present in a tank, the optional, rigid stainless steel pipes can be quick-coupled to the coil to extend the hose connections through the manhole and outside the tank. In this way, only standard glycol hoses are necessary

- Has a single lifting hook on top to allow it to be lifted and lowered through the manhole of a tank with a crane, cherry picker, forklift or similar lifting device. It is narrow enough to allow it to be lowered through any standard sized tank manhole

- An optional insulation package is available that consists of a light-weight material fitted to standard tank sizes. This offers huge energy savings and the ability to heat more tanks because of the large heat-loss reduction. Insulation wraps are also available to contain heat-loss from exposed glycol hoses

The Hydronic Heat Solutions HHR 4500 power, hydronic hose reel system brings unsurpassed portability, reliability, and convenience to ground thaw and concrete curing applications. The HHR 4500 features a compact design that holds up to 4,500 feet of 5/8” hose, filled with glycol. The system comes equipped with an electric drive motor to quickly and effortlessly reel in up to nine, 500 foot lengths of filled ground thaw hose, one at a time. The HHR 4500 is constructed of sturdy welded steel, with integral forklift pockets for easy transport and manoeuvrability on the job site. The hose spool is constructed of reinforced steel. All steel components on the HHR 4500 are powder coated for durability and longevity.

The 4500 hose reel is used in conjunction with a central Hydronic heater to provide a portable grid of hot circulating fluid to be used for purposes such as:

- Thawing ground

- Curing concrete

- Melting ice or snow

- Other custom applications

The Hose Reel 4500 can be purchased with, or without, hose.

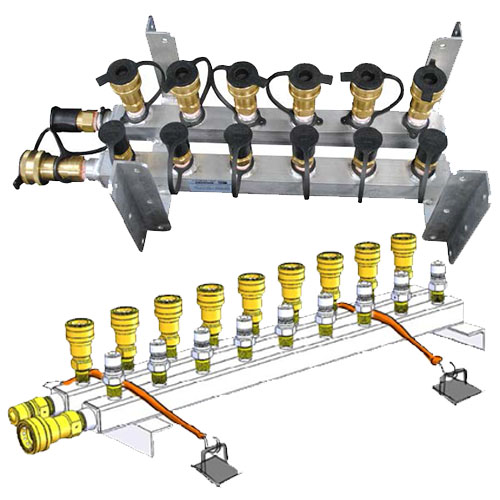

The HHS Manifolds and Hose Assemblies:

2, 3 and 4 side-branch versions are available:

- Separate supply and return assemblies together make up a set.

- Consist of NPT fittings and ISO “B” type quick couplers.

- The Primary end attachments are 1″.

- 3/4″ and 1″ branch-size versions are available.

- Used primarily when multiple fancoils are being set up

6 and 9 side-branch versions are available:

- The supply and return sides are connected together to form a single assembly.

- Consists of ISO “B” type quick couplers installed on metal tubes.

- The Primary end attachments are 1″.

- The side branches are all 3/4″.

- Used primarily for ground thaw, concrete curing and snow melting.