HERE ARE A FEW WAYS PEOPLE ARE USING OUR SYSTEMS

Our Hydronic Heating Solution systems cover a wide range of applications that span across multiple industries; here are a few of the industries in which our products are being used. For further information, please check out some of our Customer Success Stories and our impressive list of Clients.

MULTI-INDUSTRY APPLICATIONS HYDRONIC HEAT SOLUTIONS

Construction

Heat solutions for commercial, industrial and residential new and renovation projectsConstruction

The Hydronic Heat Solution for construction projects is superior in many ways to all other alternatives.

- No products of combustion or moisture are introduced into the conditioned space.

- Air within the conditioned space is recirculated to eliminate the need to heat vast amounts of outside air.

- Unlimited air ducting strategies are possible.

- Thermostatic temperature control is effective and uniform.

- Air within the conditioned space can be filtered, even to HEPA standards.

- Explosion-proof equipment is available for Volatile environments.

- Heat exchangers can be located all around the structure to provide optimum conditioning uniformity.

- Energy costs per project/per season, are lower than all other methods of temporary space heating.

Ground Thaw & Concrete Cure

Heat solutions for thawing, curing, melting and frost protectionGround Thaw & Concrete Cure

The Hydronic Heat Solution for thawing frozen ground, curing concrete in cold weather or melting snow/ice – provides the most effective & cost-efficient method in the industry.

- You can choose from a fully contained mobile system or modular components to assemble your own system.

- The use of multiple shorter hose lengths distributes the heat much more uniformly over the entire treatment area, thus increasing efficiency and the size of the area that can be treated in a single setup.

- Multiple shorter hose lengths simplify the setup procedure and required effort which increases the productivity of your crew allowing them to focus on the project at hand.

- A “high output” pump combined with the multiple shorter, parallel-manifold-connected hoses result in a significantly higher rate of glycol flow through the system.

- The manifold and treatment area can be located a distance away from the Heating unit. This makes it possible to treat those hard-to-reach areas.

Pest Control

Heat solutions for remediation of pest infestation of dwellingsPest Control

The Hydronic Heat Solution for Pest Control is the absolute best method to “seek and destroy” the Bugs, Beetles, Roaches, Rodents and even biological infestations that can invade a dwelling.

- No chemicals are used, which can affect the health of occupants after the treatment. Pests eventually develop tolerance to certain chemicals and follow-up treatments become necessary.

- Pests cannot hide from heat and it seeks them out and destroys them, even in cracks and under coverings.

- When properly applied for adequate dwell time, the heat penetrates walls, ceilings and floors and even kills unhatched eggs of the pests.

- 100% mortality is achieved with one complete treatment.

- Setup of the system is relatively easy, non-invasive and very few household items will usually need to be removed from the dwelling

- Everything you need is securely stored within the pest control unit, increasing productivity.

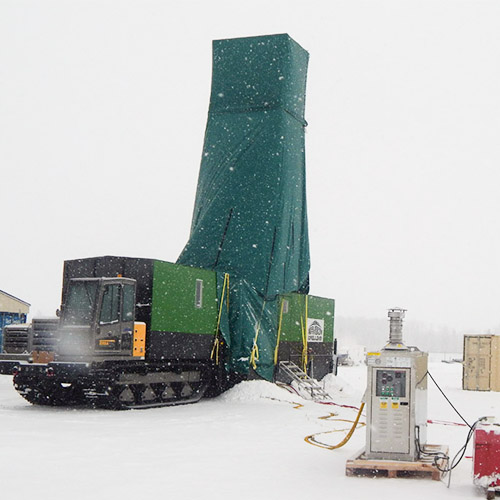

Energy Sector

Heat solutions for oil & gas, mining, diamond drilling, tanks, pipelines, etcEnergy Sector

The Hydronic Heat Solution for providing heat (to the oil & gas, mining and diamond drilling industries), is the best method to heat enclosures, tanks with liquids, pipelines and environmental containments.

- Many accessories are available to make use of the “Central Glycol Heaters” for a large variety of heat requirements.

- Explosion-proof equipment is available for Volatile environments.

- No products of combustion (and the resulting moisture) are introduced into conditioned spaces.

- Air within the conditioned space is recirculated to eliminate the need to heat vast amounts of outside air.

- Heat exchangers can be located all around the structure to provide optimum conditioning uniformity.

- Various efficiency air filters can be utilized.

- An incredible cost saving over mobile hot-oil-circulators is achieved.

- Hot glycol distributed in a non-pressure vessel circulation system is a safe reliable alternative to steam pressure vessels which are serious safety hazards and require an operator to have a pressure vessel operator’s certificate.

Agriculture

Heat solutions for drying grainAgriculture

The Hydronic Heat Solution for drying grain provides many advantages over the large direct-flame, conventional continuous dryers.

- Drying takes place in the storage bins (on the farm) and utilizes the existing aeration fan-and-duct system which means that handling of the product is, therefore, greatly reduced.

- For Hydronic systems, the products of combustion (and the resulting water vapor) are not forced through the grain as is the case with competitor’s direct burner systems. The result is, NO Contamination of the food product and less moisture to deal with.

- Optimum drying temperature for a Hydronic system is about 100°F, which will not affect the germination ability of the seed in any way. Competitor’s direct-flame systems always run much hotter contact temperatures, which result in loss of germination ability for the seed.

- The comparatively low cost, per bushel, of Hydronic drying, makes it an extremely useful harvest-management tool for the farmer. Threshing can begin when the grain is still high moisture which allows the farmer to preserve top grade product since it prevents bad weather from diminishing the quality of the grain.

- Dry grain stores longer than grain with moisture and therefore reduces spoilage

Special Applications

Heat solutions for water damage, emergency replacement and special eventsSpecial Applications

The Hydronic Heat Solution for “water damage/restoration”, “emergency heat replacement” and “heating for special events”, provides the perfect choice for all those “unforeseen emergency” and “planned short-term” heat necessities.

- When disaster strikes and buildings become flooded, there is no method that will flush the un-pumpable water from the structure as fast as evaporative dry heat accompanied by dry flow-through air. Building materials can be saved and formation of Mold prevented. Only a Hydronic system can provide the correct balance of interior heat, air movement and heated flow-through airstream.

- When a “permanent building heat system” fails or needs replacing in the coldest weather, temporary hydronic heat can be set up quickly, to maintain the comfort of even large commercial buildings. The existing distribution system can often be utilized to keep all sectors of the building comfortable.

- Whether Your Special Event is held in a huge tent or a normally un-heated storage facility or an enclosed sports practice field, your planned event will be much more comfortable with the addition of a clean, safe, portable hydronic heat system.

- In any of these applications, NO products of combustion (and the resulting moisture) are introduced into the structure.